Engineers and builders rely on structure and reliability before any machine or workstation comes to life. A well-designed framework begins with strong extruded aluminum T slot profiles, but accessories determine how well that structure performs under daily use. The right components transform a basic frame into a stable, load-bearing system that supports movement, vibration, and long-term wear.

Heavy-duty Die-cast Gussets for Reinforcing High-stress Corners

Corner joints experience the highest levels of concentrated force, making gussets essential in reinforcing these areas. Heavy-duty die-cast versions attach directly into the T slot extrusion channels, creating rigid corner connections that prevent twisting and frame deformation. Their thick cast bodies distribute stress evenly, especially in applications involving conveyors, machine enclosures, or tall support towers. A well-secured gusset also reduces the risk of joint fatigue. Rather than relying solely on tension from bolts, the gusset body adds structural mass that stabilizes the entire assembly. Projects built with MiniTec Aluminum Framing benefit significantly from these gussets because they enhance the strength-to-weight ratio of the overall system.

Powerlock Fasteners for Vibration-proof Perpendicular Connections

Sections that meet perpendicularly demand a connection that won’t loosen under vibration. Powerlock fasteners grip internally to extruded aluminum T slot channels, creating a compression-based hold without sliding. These fasteners tighten from the exterior, making installation and adjustments quick even in tight production setups.

The vibration resistance they provide is especially useful for machine guards, robotics platforms, and automated systems. Instead of relying on traditional brackets, Powerlock fasteners lock perpendicular profiles tightly together so the equipment remains stable during repetitive motion. Many teams that build with MiniTec extruded aluminum framing prefer these for their reliability and ease of installation.

Stainless Steel Tensioning Bolts for Maximum Joint Clamping Force

Tensioning bolts increase the clamping force at a joint, preventing frame members from shifting under heavy loads. Stainless steel versions resist corrosion, ensuring connections remain strong in humid or industrial environments. Their fine threading allows for precise tightening, which helps maintain alignment in equipment that must remain square and stable.

The improved clamping strength is essential for frames supporting dynamic loads, such as automated pick-and-place arms or heavy tooling tables. By tightening directly into the T slot aluminum extrusion channels, these bolts deliver dependable performance that supports long-term system integrity.

Cross-block Connectors to Bridge Multiple Parallel Profiles

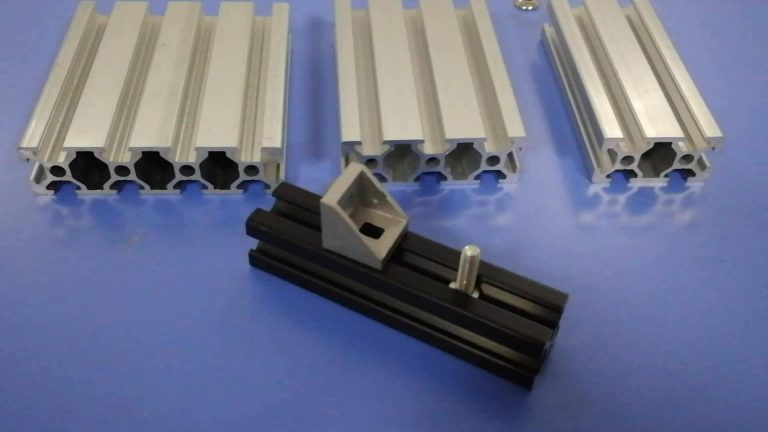

Parallel profiles often need linking to support additional equipment or to increase overall rigidity. Cross-block connectors fasten two or more parallel extruded aluminum T slot profiles together, forming a reinforced beam. Their design creates a stable cross-section that reduces bending or twisting under side loads.

This accessory is especially helpful in conveyor systems, safety barriers, and modular machine structures where support must run across long spans. With cross-blocks installed, the load distributes across multiple profiles instead of a single rail, delivering a more reliable structural outcome.

Steel Base Plates for Securing Frames Firmly to Factory Floors

Base plates anchor an entire framework to the floor, making them essential for tall or load-bearing structures. Steel versions provide weight and rigidity, preventing the frame from shifting during operation or accidental contact. They bolt directly into the T slot extrusion channels, forming a wide, secure footprint.

Anchoring improves stability in areas where machines vibrate or where equipment might be bumped by carts or forklifts. With steel base plates installed, frames built with MiniTec Aluminum Framing maintain consistent alignment even in high-traffic industrial settings.

Internal Miter Connectors for Rigid, Hidden Angled Joints

Angled joints are often difficult to reinforce without bulky external brackets. Internal miter connectors solve this by fitting inside the extruded aluminum T slot cavity, allowing angled cuts to join seamlessly. These connectors create strong, hidden joints that maintain the frame’s clean lines while supporting weight effectively.

Their internal design keeps surfaces flush, which is important for enclosures, display frames, and architectural structures. Hidden joints not only improve aesthetics but also reduce snag points in work environments where safety and smooth surfaces matter.

Bracing Struts to Eliminate Sway in Tall Vertical Structures

Vertical structures naturally sway unless reinforced. Bracing struts connect diagonally between profiles to counter lateral forces, stiffening the entire frame. These struts attach directly to T slot aluminum extrusion channels, forming triangles that distribute force and resist movement.

The increased stability is especially valuable for tall machine towers, guard barriers, and support rigs. Adding bracing ensures the framework maintains its shape even with vibrations or side pressure from equipment movement.

Double-bridge Cladding Profiles for Increased Torsional Stiffness

Cladding profiles improve torsional stiffness by increasing the frame’s outer surface area. Double-bridge versions lock into extruded aluminum T slot channels, forming a reinforced shell around the structure. This boosts resistance to twisting—a common issue in long or narrow frames.

Applications such as material handling systems, inspection tunnels, and modular shelters benefit from this added stiffness. The profiles also serve as protective surfaces, shielding internal components from dust, debris, or impact.

Threaded Inserts That Provide High-Strength Mounting Points

Threaded inserts transform a hollow T slot extrusion into a strong mounting point capable of holding tools, sensors, or safety components. These inserts expand as they tighten, gripping the interior walls of the profile securely. Their metal threading supports repeated tightening and removal without wearing down.

They allow accessories or add-ons to be mounted wherever needed along the extrusion. The flexibility to mount equipment anywhere on a MiniTec extruded aluminum framing system makes threaded inserts essential for modular design and quick upgrades. For anyone planning to strengthen an industrial framework with reliable accessories, Minitec Solutions offers components designed to deliver long-term stability and performance across demanding applications.